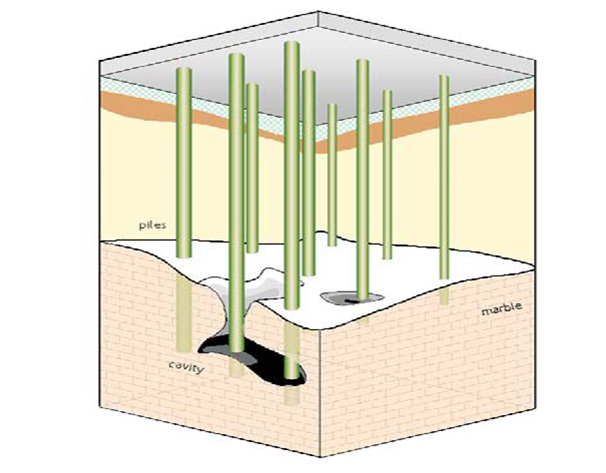

What Is Micropile Kinds Of Micropile Usual Uses Micropile Advantages & Downsides Of Micropiles Micropile Vs Regular Heap How Are Micropiles Set Up Are generally adopted to transfer the tons from the superstructure via weak strata onto the stiffer dirts or rocks. Therefore, the dependability of pile-supported structures depends largely on the actions of the heaps. An important design factor to consider is to inspect the load-- settlement qualities of stacks. Owing to its intricacy, heap settlement lacks an accurate analytical theory or understanding of the phenomena involved. The micropile covering typically has a size in the series of 3 to 10 inches. Strengthening steel, normally an all-thread bar is put right into the case. The housing might extend to the complete deepness or end above the bond zone, with the reinforcing bar extending to the complete deepness. For the most usual kind of mini loading, a hollow steel shaft is either screwed or drilled into the ground. Cement or concrete can after that be gathered to develop the heap, with the dirt supported throughout by the steel shaft. This indicates that, unlike the conventional boring method, no extra assistances are needed, even in weak soil. Changed after Rotta Loria, A.F., Català Oltra, J.V., Laloui, L., 2019b. Comparable pier evaluation of full-scale pile teams subjected to mechanical and also thermal lots. The shaft as well as base abilities of the equivalent pier were determined by increasing the shaft and base abilities of the single separated piles increased by the variety of piles in the team.

- Micropiles are slim columns of deep structures with reasonably tiny diameter and low lots bearing capacity that are mounted fairly close to each various other.The lots consequently bypasses the weak layer and also is safely transferred to the strong layer.The heap moves the load of the structure to the dirt throughout the full elevation of the stack, by friction.Micropiles can be used in nearly any type of subsurface dirt or rock because they can be inserted utilizing exploration devices and also combined with numerous grouting treatments to form the bearing aspect.The case might reach the full depth or end over the bond zone, with the enhancing bar extending to the full depth.One more typical item is an unabridged steel threaded bar made of grade 40 (275 N/mm2) to 150 ksi (1035 N/mm2) steel.

How Much Does It Set You Back To Set Up A Micropile Foundation, As Well As That Should Be In Charge Of The Installment Process?

After Tremie grouting, do a stress grouting through preinstalled grouting tubes. Micro-pile systems are most prominent to sustain as well as support structures, bridges, highways, towers and different unreal frameworks, either as new structures or restorative construction. Grouting is achieved by tremie grouting, stress grouting throughout casing retraction, and tremie-grouting with post-grouting. Micropile foundation is among the very economical as well as trusted pile structures. For heaps support, a steel support cage of a package of large size rebars is utilized. After the screening of the enhancing bar, the rebar is cut as well as the head is oiled for security from the weather condition components. Replacement stacks are built within a formerly pierced borehole, hence restoring the excavated ground. The drilling of boreholes with casings is done utilizing an ideal boring method for the soil/site problems. Later on the exploration pole and also exploration bits are removed and enhancing bars are inserted right into the boreholes. Grouting is then performed in sequence under pressure and also the casing http://elliottjhau742.wpsuo.com/piling-as-well-as-foundations-ground-engineering-expertise is gotten rid of slowly. If the sapwood of timber heaps is worn away, the remaining heartwood area may still have enough load-carrying ability.Underpinning

An exploration strategy that is proper for the soil/site problems is used to drill boreholes with coverings. Adhering to elimination of the boring rod and also devices, support bars-- normally corrosion-resistant steel bars-- are next positioned right into the boreholes. Next off, grouting is carried out sequentially under stress as the casing is progressively eliminated. Certain dirt conditions will certainly obstruct setup as well as even thwart the development of standard base solutions. When such conditions exist, qualified and also grouted micropiles offer mini piling services north west an economical, deep structure possibility with the ability of passing through obstructions attached amongst proficient bedrock.Top 8 Tips For Wheel Loader Operators - For Construction Pros

Top 8 Tips For Wheel Loader Operators.

Posted: https://www.blurb.com/user/atxbfdt113 Tue, 06 Sep 2022 07:00:00 GMT [source]